This leading signage printer, manufacturer and installer recognised the time had come to enhance their existing offering with a direct to substrate flatbed printer. Widely recognised for their vinyl production of window graphics, interior and exterior displays and signage plus vehicle livery; they were keen to expand their offering.

Coinciding with their move to new, larger premises in Wetherby at the end of 2019, this innovative signage provider now had the space to look at other machines with a view to being more efficient with time and effort. They identified a need to look for a printer that could take some of the capacity from their roll-to-roll printers to free those up to solely produce vinyl wraps and flexible signage. So, the search was on to find a new printer to tackle the flat direct to substrate work.

As Simon Bell, Director at AD Bell says;

“We’ve been going for over 20 years and during that time have constantly innovated and broadened what we are capable of producing. A lot of the work we do is vinyl vehicle wraps using roll-to-roll printers; however we also frequently produce large scale flat signage too. Previously, this has been produced by printing the vinyl on a roll machine and then sticking it to board. However there is always a risk involved in doing it this way in terms of durability and resilience, which is why we wanted to look at some flatbed printer options.”

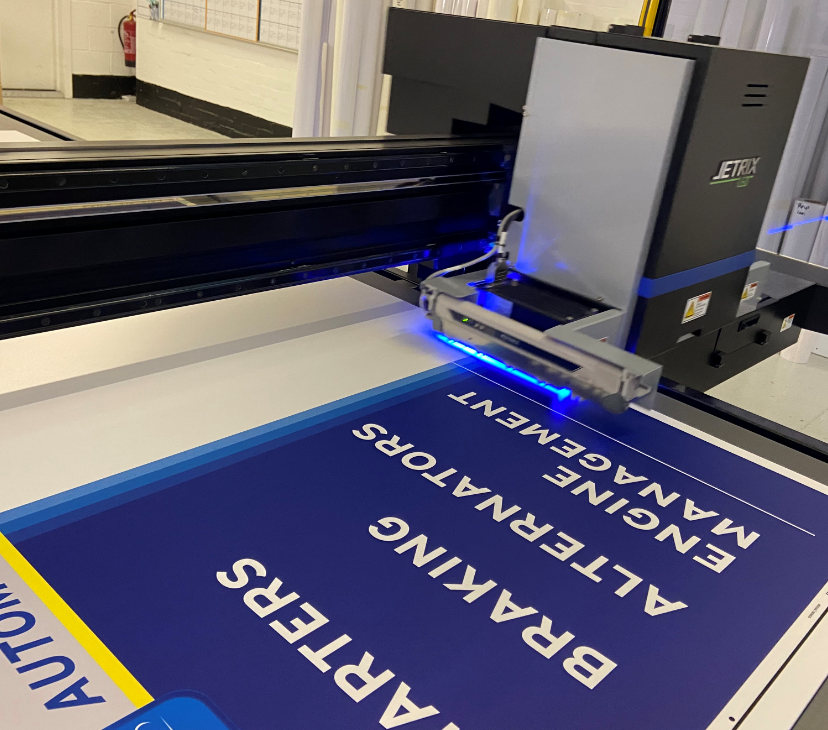

Working with Darren Walker from Perfect Colours, a number of machines were explored; however the JETRIX LXi7 repeatedly came out as the preference. Talking with Darren, he said:

“Perfect Colours have been dealing with AD Bell for a few years, supporting them as the business has developed. We have been working with them to explore and introduce more digital wide format capabilities and applications which in turn will create additional opportunities for them.

Having recently acquired a flatbed cutting solution, they next wanted to invest in the very latest flatbed printer. After extensive research of the market the obvious product was the JETRIX LXi7. So, after successful demonstrations, we also went through a comprehensive testing of substrates that other printers often find challenging including plastic, glass and Perspex. This was to make absolutely sure the printer could meet their immediate and longer term aspirations of working with a wide variety of substrates.”

The extensive research process obviously involved seeing the printer in action, but the team at AD Bell also put a significant focus on putting several samples through more extreme testing conditions. The experienced team that were going to be using the printer were only too aware of the issues some direct to substrate exhibited. They were therefore keen to avoid these problems, such as chips when routing or drilling and print easily scratching off. However, despite their best efforts the JETRIX LXi7 with its powerful zonal vacuum system, LED UV technology and advanced user-friendly GUI software repeatedly met and exceeded this stringent testing. In fact this; combined with the extended warranty, leading head technology and the outstanding colour with high level of adhesion that the InkTec inks achieve, meant the JETRIX LXi7 was the perfect machine.

Simon continues;

“While the cost of the JETRIX was extremely competitive compared to the other options out there, our purchasing decision was based on much more. For us, we were also keen to look at understanding the lifetime running costs, the quality and cost of inks and their durability. As a result, all of these factors were paramount in making our decision.

The JETRIX really does do exactly what it promised and more. It is faster than our existing roll-to-roll printers and so is doing things quicker and eliminating the additional stages in the process that we were going through using the roll-to-rolls. The colour gamut is absolutely fantastic and in fact the 6 colours are so much punchier than what we are getting from the other printers. The comprehensive training by the engineers when it was installed and the cleaning management programme means that it is always ready to print when you need it.”

Ben Woodruff, Head of JETRIX UK Sales at InkTec Europe comments;

“The JETRIX LXi7 is the perfect machine to venture into the direct to substrate market. Its ability to tackle large scale media with thicknesses up to 100mm makes it an extremely versatile piece of kit. This combined with the innovative LED curing system, reduced operational costs as it has an overall lower energy consumption and longer lamp lifetime means it is proving a popular large format printer.”